LCD screen maintenance equipment manufacturer

Difficulty Assessment of Screen Pressing Machine Operation

The difficulty of operating a screen press machine is affected by the type of equipment, the experience of the operator, and the maintenance scenario. It needs to be comprehensively judged from the following aspects:

1、 High difficulty operation stage

High precision alignment requirements

The alignment of COF cable or screen components requires micrometer level accuracy, which cannot be achieved by the naked eye, and relies on the device’s built-in camera lens and fine-tuning platform to assist in positioning.

Parameter adjustment relies on experience

Temperature (such as 70-100 ℃) and pressure (such as vacuum chamber pressure) need to be dynamically adjusted according to different screen materials (OLED/LCD/flexible screen). Improper settings can easily lead to virtual soldering or short circuits.

Significant device dependency

The professional screen press integrates multiple functions such as lamination, defoaming, and curing. The operation process is complex and requires familiarity with the equipment interface and functional module switching.

2、 Technical optimization to reduce difficulty

Intelligent devices simplify operations

Desktop screen press machine supports automated detection of pressure and temperature, one click start of bonding process, reducing manual intervention.

Modular Process Design

High end models break down the steps of cleaning, pressing, and testing into independent modules, which beginners can gradually learn.

Auxiliary tools improve fault tolerance

Tools such as conductive tape and screen pressing molds can assist in fixing components and reduce the risk of manual operation errors.

3、 Applicable scenarios and personnel recommendations

Low difficulty scenarios: replacing the outer screen glass (rear screen pressing), repairing small areas of delamination, etc., can be mastered by ordinary maintenance personnel through short-term training.

High difficulty scenarios: repairing COF cables, handling flexible screen cracks, etc. require professional equipment support and long-term experience accumulation.

Summary: The difficulty of operating screen presses is polarized, and intelligent devices and standardized processes have lowered the threshold for basic maintenance. However, precision maintenance still requires professional knowledge and equipment proficiency support.

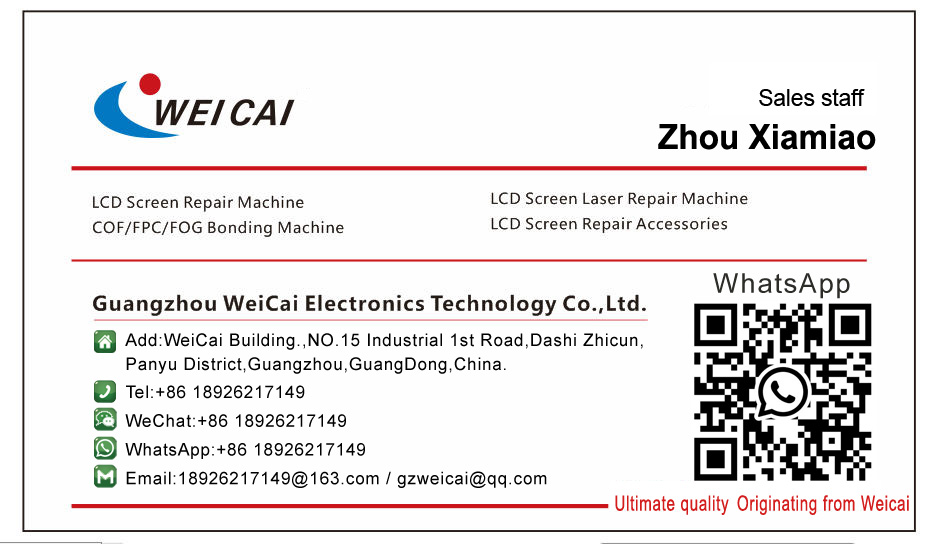

For more detailed information, please feel free to contact me