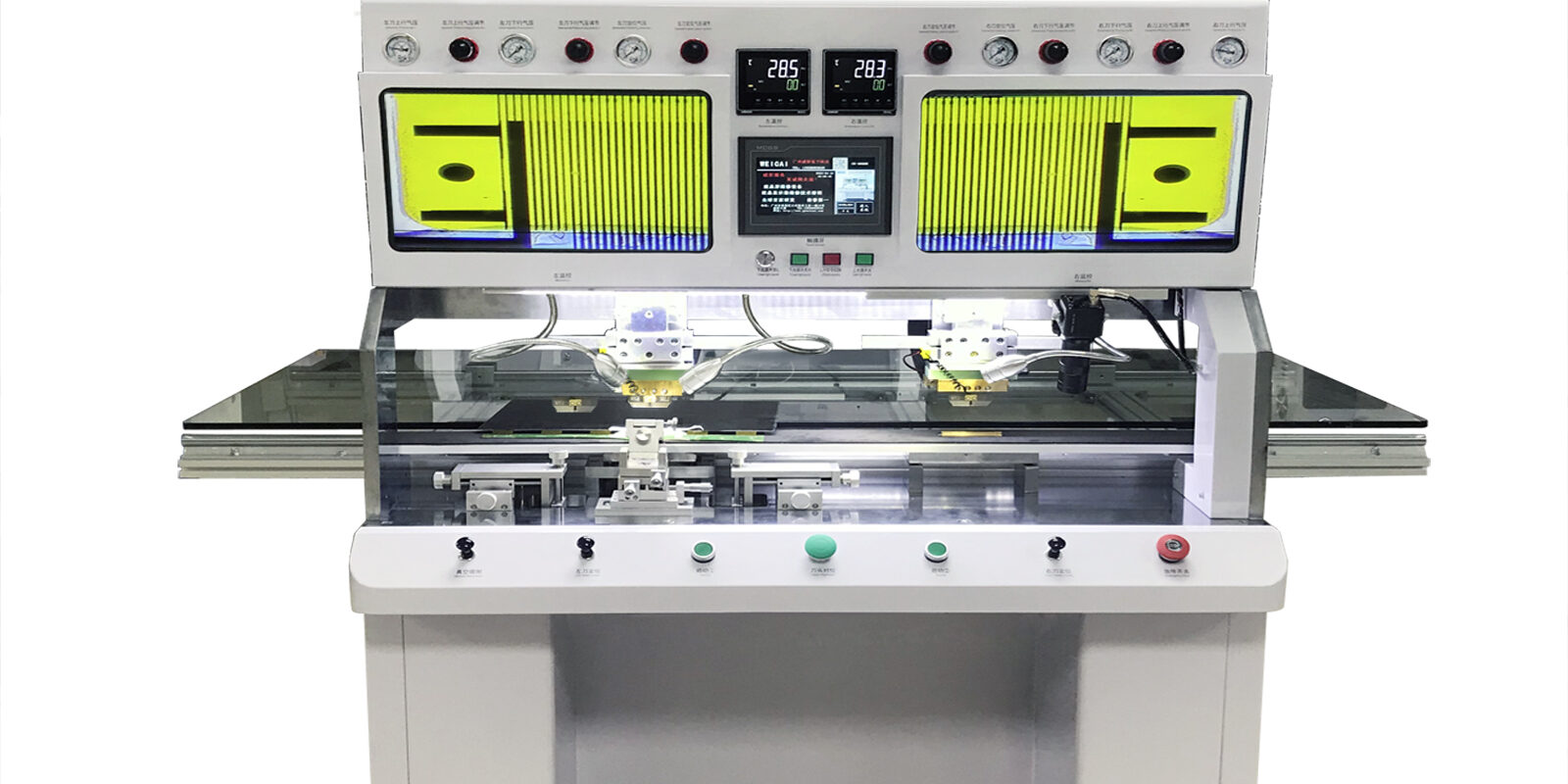

1. What is LCD TAB bonding machine/screen repair machine/hot press machine/screen press machine maintenance machine?

It is a common production tool, whose main function is to connect TAB/COF (module) and conductive adhesive explosive particles through pressure and contact with the material surface to achieve the purpose of pressing. Suitable for home appliance repair and TV repair manufacturers, regular equipment supports 14-65 inches, and larger sizes can be customized according to needs to increase the size by 75-85 inches These machines are essential for extending the lifespan of LCD displays.

2. Overview of the LCD TAB bonding machine/screen repair machine/hot press repair machine market?

In 2024, as the demand for LCD screen repair solutions increases globally and sales grow, equipment is essential for home appliance repair customers in the national market. The current price ranges from $2500 to $5300, depending on the characteristics of the machine. Small home appliance repair shops and LCD screen after-sales service providers are used to select equipment that is easier and more suitable.

3. What are the key factors affecting the price of LCD bonding machines/screen repair machines/hot press machines?

The evaluation is based on the selection of different models, the selection of suitable products, and other factors that can be considered.

Requirement: Due to different internal configurations and machine sizes, better functionality of the equipment means higher prices,

Individual home appliance maintenance: Small machines and equipment are sufficient to meet the requirements for use

Professional brand after-sales service: requires equipment with high requirements, quality assurance and maintenance standards, etc. It is often recommended to choose the most high-end equipment

Supply chain and market demand: Supply chain fluctuations, material supply, and regional demand also affect final prices. High demand or high supply constraints may drive up costs.

4.What is the typical price range for LCD bonding machines/screen repair machines/hot press machines?

Small home appliance repair and use: priced at $2500, individual home appliance repair is already very suitable

Medium sized models: priced at around $3800, mid sized machines offer more precise additional features

High end equipment: priced at 5300 US dollars, professional maintenance equipment, using high-precision temperature control, high-density LCD screen temperature requirements, small errors, high success rate in the maintenance process, and few repairs.

5. Choose the appropriate LCD bonding machine/screen repair machine/hot press repair machine for your business?

To purchase suitable equipment, for example; If you are a small repair shop, small appliances or medium-sized machines are sufficient, but if you handle a large number of repairs, high-end machines can improve efficiency and help maximize profits.

6. Evaluate cost-effectiveness and return on investment?

Evaluate the cost-effectiveness of the design of the LCD bonding machine and its initial price Important considerations include

Repair speed: The speed at which machines handle repairs directly affects your productivity.

Durability: Machines have a longer lifespan because they require less repair and replacement.

Customer support: Reliable brands typically provide excellent after-sales support, reducing maintenance related risks.

Easy to use, machines with convenient user control can reduce the need for extensive training of staff, thereby saving labor costs.

7. What are the long-term costs of operating LCD bonding machines/screen repair machines/hot press machines?

LCD screen maintenance requires long-term costs such as TAB materials:

Maintenance cost: Regular maintenance is necessary to keep the machine running at its best.

Business expenses: Energy consumption, labor required for machine operation, occasional replacement of parts, increase overall costs. Machines with high levels of automation can reduce operating costs by reducing the number of manual operators.

8.Conclusion: Make the best purchasing decision?

In selecting the best repair process, please carefully evaluate and choose the most suitable style, or communicate with the salesperson to explain the situation and make recommendations. Always consider choosing the best one that can meet your repair needs and maximize the return on investment.

Depending on your business needs, entry-level or medium-sized machines may be the most valuable for small equipment repair shops. For professional manufacturer maintenance and for larger businesses, high-end models can ensure higher efficiency, improved speed, and quality.